How to replace Spigot Bush

If you have the engine

out and are replacing the clutch, or you are getting

an awlful screaming noise from the rear of the car

in the area of the clutch, you should replace your

spigot bearing!

There are two types of spigot bearing, the most

common and fitted to the majority of imps is a solid

phosphor bronze bush, very late cars have a needle

roller bearing instead.

This article covers replacing the phosphor type

Tools Required

Soft Mallet / Soft Drift, Hammer, 'Close Fitting

Tool' gearbox input shaft, long M10 Cap screw or

something you have found in the shed!, 1/2" AF

Spanner for Clutch Cover Bolts, Molygrease / LM

Grease, Clean/Fresh Engine Oil to soak the new bush

in.

- Believe it or not

but this solid looking metal bush is full of

little holes, these provide a reservoir for oil,

but you need to get some oil in them holes!

The supplier of this bush had penned a handy

reminder on the popper bag! You need to soak in

engine oil for a while (I left this one for a

week) but a day or two is fine.

*DO NOT just

coat in oil and fit, it is simply not enough

time for the bush to soak up any oil. So get one

in advance!

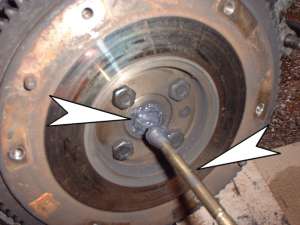

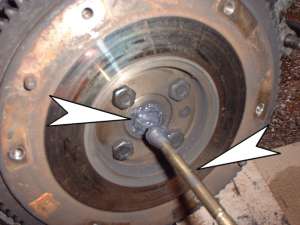

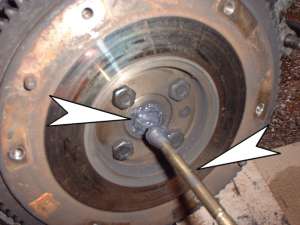

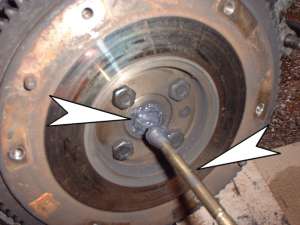

- If you haven't

done this already, then remove the clutch cover,

a little tip is that if you position the spanner

as the picture shows, you can use a soft mallet

on the spanner to loosen the cover bolts without

locking the flywheel - this works if the force

of the mallet blow is towards the crank. If you

can't loosen the bolts with this method, as the

flywheel keeps turning, then use a large flat

bladed screwdriver against one of the flywheel

teeth and a bellhousing stud - to hold the

flywheel, whilst using a spanner to undo the

cover bolts.

- *NOTE once you

have loosened the cover bolts, undo them evenly

to slowly release the cover pressure!

Remove the clutch cover and the friction plate -

don't drop them or get grease/oil on them!

Now you can see the spigot bearing (gold bit),

note its position in the crank - passed the

large chamfer in the end of the crank.

How an earth do you get that out?

- There are a

number or methods to get the bush out.

* You can use a Rawl Bolt and a slide hammer

* A proper bearing remover!

* Drill it out and pick the remains out

or use the 'Power of Hydraulics'!

- For this method

you need to find something that is a close (but

not tight!) fit in the spigot bearing, suitable

things are an old gearbox input shaft, the head

of an M10 cap screws is about right, I'm using

the centre part of one of those clutch alignment

tools

You need then to pack the spigot bearing/crank

hole with grease - LM or Molyslip will do - try

not to trap air in the hole.

- Now place you

close fitting tool just a little way into the

spigot bearing - if there is little or no air,

you should feel resistance - if not repack with

grease to get rid of the air.

Now with a mallet/hammer give your close fitting

tool a sharp tap, pushing it into the spigot

bearing hole. With a bit of luck you should see

the spigot bearing pop out a bit!

Repeat the steps above until the spigot bush is

all the way out (this one took 3 goes!)

- Clean out all the

grease! Do not get any on the flywheel!

- Remove the bush

from its oily pool, give it a quick wipe and

offer up to the the end of the crank.

GENTLY tap in using a plastic drift (or soft

mallet if you are very careful) make sure it

goes fully passed the chamfer in the crankshaft

(see step 3) DO NOT use a metal hammer, as you

will bur the bush!

Job Done!

(c) Andy Smith 2025